METAL CORE PCBs (MCPCB) ALUMINUM PCBs

From: Author:PCBs Publish time:2021-09-15 17:03 Clicks:0

Metal Core PCB (MCPCB) or Insulated Metal Substrate (IMS PCB) is a technology developed to overcome the thermal limitations of the FR4 material. Metal Core is a better choice than FR4 if your boards need to perform in high temperature environment.

Insulated Metal Substrate provides electrical isolation between the copper and the metal core by using a special dielectric with the peculiarity of having high thermal conductivity.

The most common material used in the substrate is aluminum, for this reason, these type of boards are usually known as Aluminum PCBs.

METAL CORE PCB APPLICATIONS

PCBs that require a lot of power usually generate a lot of heat. If your PCBs need fast cooling it is better to use Metal Core PCB than FR4. The following list includes some of the most popular applications that work great with this technology:

- LED Lighting

- Power Conversion Systems

- Power Supplies

- Photovoltaics

- Telecom & Industrial

- Automotive Electronics

METAL CORE PCB TECHNOLOGY BENEFITS

Insulated Metal Substrate Technology offers a great list of benefits when an application requires great heat dissipation.

Most engineers and designers rely on Metal Core PCB to take advantage of the following benefits (compared to FR4 PCBs):

- Superior heat dissipation

- Eliminate heat sinks and other voluminous hardware

- Great durability of Aluminum

- Lightweight and strength

METAL CORE PCB STACK-UPS

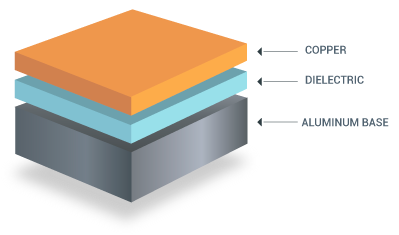

It consists of a single copper conductive layer on top, a

metal base plate (e.g. Aluminum) to provide rigidness to

the circuit board and a thermal conductive dielectric

working as the insulator.

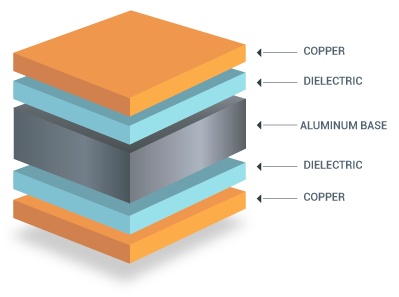

It has two copper layers and the metal core is between thecopper layers. Plated Through Holes (PTH) are used tointerconnect the acopper layers so SMT and THT componentscan be placed on both sides.

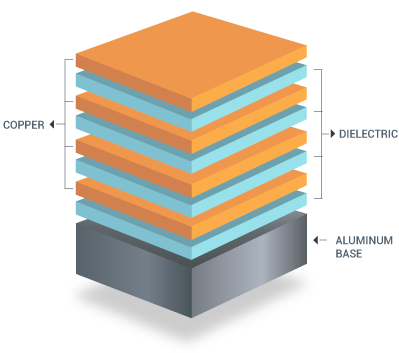

It has more than two conductive layers separated by thermaldielectric. In the bottom of the structure is the metal base. SMTcomponents can only be placed on one side. Not THT components are allowed, but it provides the possibility to make blind and buried vias with internal signal layers and power/ground planes.

SPECIFICATIONS

| ITEM | DESCRIPTION | SYMBOL | STANDARD | ADVANCED |

| No. of Layer Count | Max Layer Count | NA | 1-4 layer | 1-8 layer |

| T-clad Laminate Supplier | Laminate Supplier | NA | Bergquist, polytronics, boyu | Bergquist, polytronics, boyu |

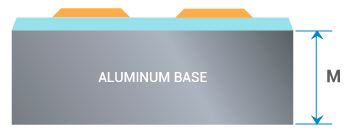

| Metal Thickness | M | 0.4-3.2mm | 0.4-3.2mm | |

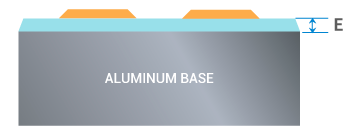

| Dielectric Thickness | E | 100-200um | 100-300um | |

| Thermal Conductivity | NA | 1W/m-k , 2W/m-k 3W/m-k | 1W/m-k , 2W/m-k 3W/m-k , 4W/m-k | |

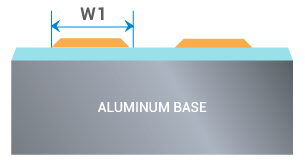

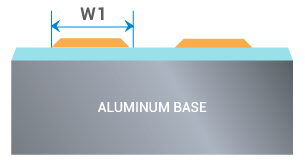

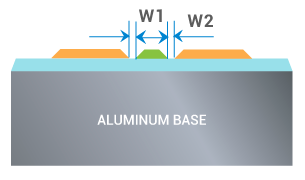

| Circuit Width | Outer Layer Min. Circuit Width | W1 | 0.15mm | 0.15mm |

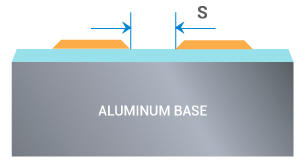

| Circuit Spacing | Outer Layer Min. Circuit Spacing | S | 0.15mm | 0.15mm |

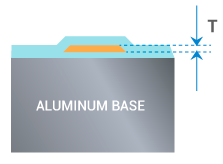

| Copper Foil Thickness | Copper Foil Thickness | T | ½- 4 oz | 1/3 –6 oz |

| Finished Hole | Min. Finished Npth Hole Size | X | 1.0mm | 0.80mm |

| Npth Hole Tol. | A | /-0.05mm | +/-0.05mm | |

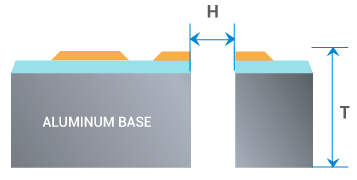

| Max. Aspect Ratio | Max. Aspect Ratio | T:H | 8:1 | 10:1 |

| S/M Dam & Clearance | Min. S/m Dam | W1 | 0.10mm (Green S/M); 0.13mm (white S/M) | 0.10mm (Green S/M); 0.13mm (white S/M) |

| Min. S/m Clearance | W2 | 0.075mm (Green S/M); 0.075mm (white S/M) | 0.05mm (Green S/M); 0.05mm (white S/M) |

METAL THICKNESS

DIELECTRIC THICKNESS

CIRCUIT WIDTH

CIRCUIT SPACING

COPPER FOIL THICKNESS

CIRCUIT WIDTH

MAX. ASPECT RATIO

S/M DAM & CLEARANCE

Keywords:

SMT Belt Line, Laser Marking SMT Line, High Vacuum Reflow Oven V3Hv, DIP Mini Wave Soldering Machine, LED Light Making PCB Assembly Machine Chip Placement Mounter SMT PICk, Chip Mounter, SMT Chip Mounter, Chip Mounter Line, PCB Chip Mounter, LED Chip Mounter, Water Cleaning Machine For PCB, PCB Cleaner ChemICal, PCB Cleaner Spray, Cleaner Cleaning PCB, PCB Resins Cleaner, PCB Air Cleaner, PCB Contact Cleaner

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com