FLEX & RIGID-FLEX PCBS

From: Author:FLEX & RIGID-FLEX PCBS Publish time:2021-09-15 17:01 Clicks:0

PROTOTYPE & PRODUCTION

- Trace and space capabilities down to.003"/.003" (0.5 oz.), .004"/.004" (1 oz.).

- Microvia diameter from .003"

- Lead times as short as 5 days.

- Multiple Offshore partners quoting system to offer excellent pricing (ISO:9001 certified).

- Selective plating of gold on the same flexible circuit.

- Minimum Tolerance of ZIF Connector to Edge of Flex +/- .003".

FLEX PCB AND RIGID-FLEX CIRCUITS

Flex Circuits, usually known as Flex PCB, are changing the way that electronics industry is creating new products, initially developed to replace wire harnesses, the Flexible Circuit technology is now breaking the old fabrication paradigms where the size of the PCB was a determining factor in electronics designing.

Through the years PCB Unlimited has built a network of manufacturing partners that include the most Flex PCB savvy factories offshore and in the US. Offering a wide range of high quality solutions, from single sided Flexible Circuits to Rigid-Flex boards, at the best prices.

FLEX PCB TECHNOLOGY APPLICATIONS

At today's world Flex Circuits can be found almost anywhere from gadgets as laptops, tablets, cell phones and smartwatches to airplanes and unmanned vehicles. The list of applications for Flexible Circuits keeps growing and growing.

We provide Flex PCB solutions to companies from the following industries:

- Aerospace

- Automobile industry

- Computers

- Consumer electronics

- Telecommunications

- Medical instruments

FLEX PCB TECHNOLOGY BENEFITS

There is a large list of benefits offered by the Flexible Circuit Technology, it can considerably improve the physical characteristics of a design by reducing both weight and size. The cost and performance advantages of using Flexible Circuits are also points that engineers and designers keep in mind, since this technology is able to offer the following benefits:

PERFORMANCE VS RIGID PCB

- Superior heat dissipation.

- Dynamic Flexing.

- Lower inductance (vs traditional wiring systems).

- Superior package density.

COST VS RIGID PCB

- Wiring harnesses substitution that lead to wiring errors elimination.

- Improved reliability.

- Assembly time and effort reductions that lead to drops in the final assembly costs.

FLEX CIRCUITS STACK-UPS

Consisting of a single thin conductive layer, hot-pressed and glued together with a flexible dielectric film to provide electrical insulation and protection from the elements, a single sided Flex PCB is the most basic and most common type of Flex Circuits.

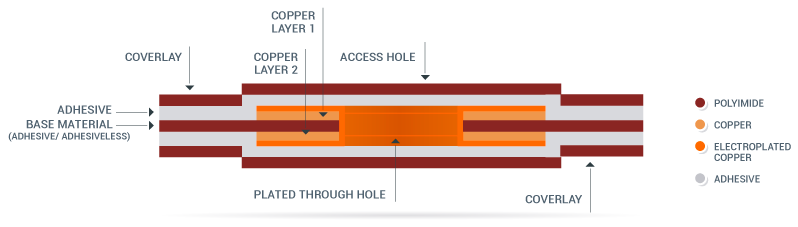

Starting with a Polyimide film as a base layer, two separate conductive layers are then glued and hot-pressed together to both sides of the film. Plated Through Holes (PTH) are used to interconnect the copper layers, and additional layers of polyimide on both sides of the panel brings insulation to the double sided Flex Circuits.

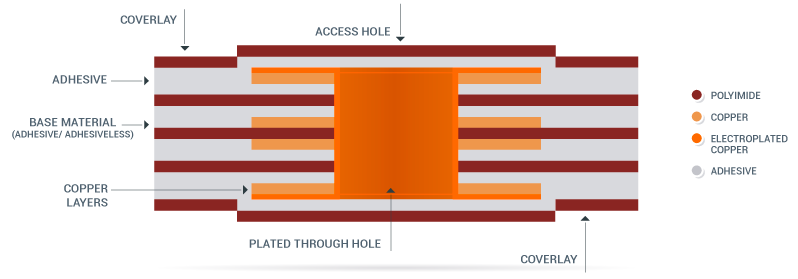

Containing three or more conductive layers, Multilayer Flex circuits manufacturing is performed combining double and single sided Flexible constructions, using adhesive layers to bond them together and interconnecting them by means of plated Vias. Circuit protection and electrical insulation is provided by a Coverlay (usually Polyimide).

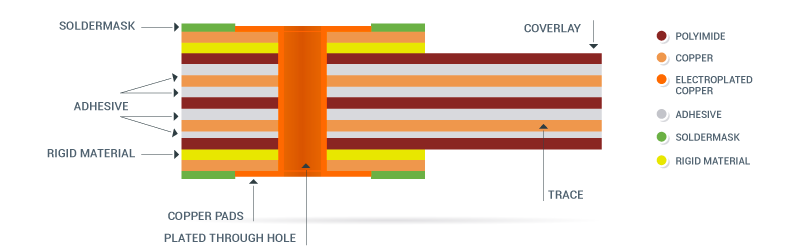

Rigid-Flex Circuits are obtained by laminating together flexible and rigid substrates, providing the design not only with strength but with dynamic adaptability as well. The rigid parts are often used to carry components and the flex substrates serve as interconnection paths.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

LED SMT Line, Shenzhen SMT Line, Desktop Reflow Oven, DIP Soldering Machine Mini Wave, SMT Chip Mounter Machine, SMT Machine Chip Mounter, PCB LED Chip Mounter, LED SMT Chip Mounter, SMT LED Chip Mounter, PCB Support Pin For Chip Mounter, PCB Acide Cleaning Machine, AssembLED PCB Cleaning Machine, PCB Brush Cleaning Machine, PCB ChemICal Cleaning Machine