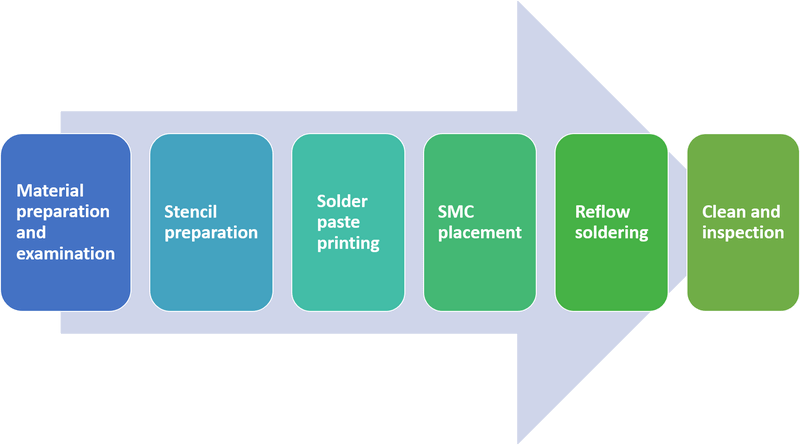

Working flow of the SMT line

From: Author:SMT line Publish time:2021-09-15 11:38 Clicks:0

How does the SMT line work?

- The basic working flow for SMT line is listed below:

SMT Working Process

SMT Working Process

①Material checking→②Loader for loading the PCB material→③Solder printing machine for printing→④SPI inspection machine →⑤pick and place machine for the component on the PCB board→⑥AOI checking →⑦Reflow in reflow oven→⑧AOI checking→⑨Unloader for unloading the finished PCB board.

- The basic working flow for SMT line for the function for each machine is listed below:

①material machine for checking or Manual detection;

②Loader is for load the pcb in a row in the setting cycle timing;

③Solder printing machine is using the palette knife to put the solder even on the panel of PCB for reflow;

④SPI inspection machine. solder paste inspection is using the optical principle. such as laser technology. to calculate the solder paste thickness printed on PCB by trigonometry.

The test standard is that the area covered by solder paste on each pad shall be greater than 75% of the pad area;

⑤Pick and Place machine is for putting the surface original component like electric resistance/capacitance/diode/TR in the right precision position which requires the very high speed.this machine plays a very key important role in the SMT line;

⑥.AOI machine is for checking the quality especially the defect after the pick and place machine finished its job;

⑦Reflow Oven is for melting and cooling the solder which is located between the original component and the PCB board according to the international temperature standard control.

then the component and PCB board can be melted strongly together and meet the electronic performance. also to needs to be effectively protected from thermal damage and deformation;

⑧AOI checking is for finished original component and PCB board after the process of reflow oven.

Its function is to inspect the welding quality and assembly quality of the pasted PCB.

The equipment usually has magnifier and microscope. it automatically scans PCB through camera. collects images. compares the tested solder joints with the qualified parameters in the database.

then it checks the defects on PCB through image processing. and displays / marks the defects through display or automatic mark for repair by maintenance personnel.

⑨Unloader for unloading the finished PCB board.

Keywords:

LED Bulb Assembly Line, LED Bulb Machine AutomatIC Assembly Line, Solder Paste Printer Fully AutomatIC, Solder Paste Printer PCB, Small Reflow Oven, Reflow Oven Rails, Wave Soldering Machine For Large Parts, SMT PICk And Place Machine Set, SMT PICk And Place Machine Oven, SMT Mounting Machine For LED Bulb, Full AutomatIC SMT PICk And Place Machine, Multi-Function SMT AutomatIC Labeling Machine, SMT Unloader New Type, Equipment PCB Conveyor, PCB Multi Rack Loader, Loader PCB, Automat PCB Loader, PCB Drop Loader, SMT Small PCB Loader, Loaders And Unloaders PCB, PCB Inverter Conveyor, PCB Buffer Conveyor

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com