Online Automated Optical Inspection Machine

From: Author:Online AOI Publish time:2021-09-15 11:03 Clicks:0

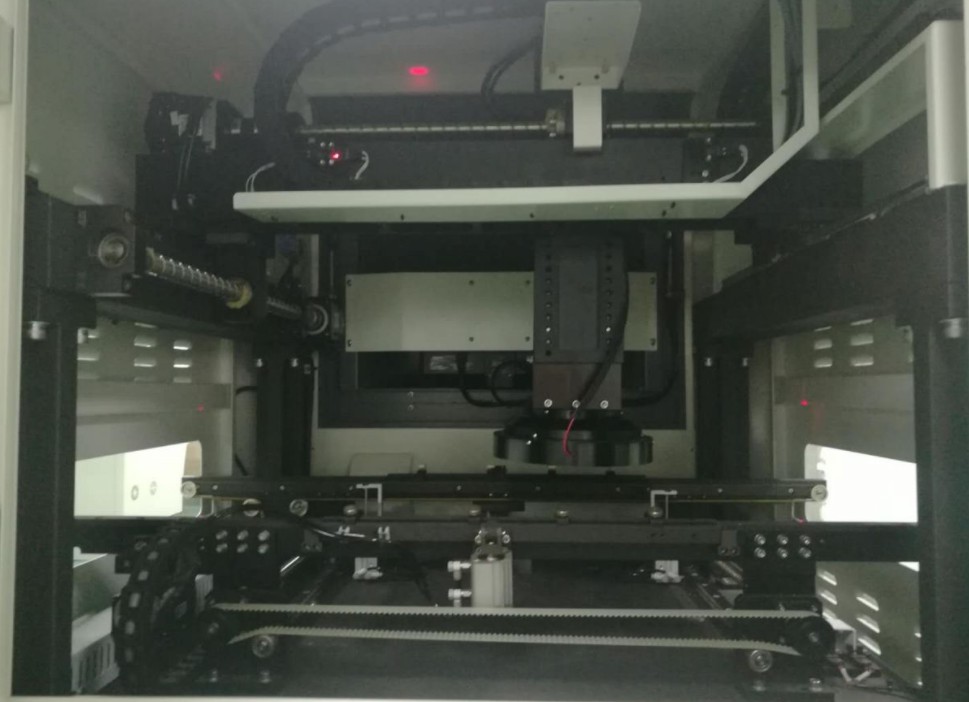

Online Automated Optical Inspection Machine

Basic Description

The model of AOI-V5000 has a better performance than the off-line model for its automatic mode, larger size of inspection item, and connectable with other on-line machines. It can inspect various items and taking an extremely clear image of the item by an ultra-high-pixel industrial camera.

And then, the data can be calculated in an intelligent and automatic method to minimize the processing time. With an automatic board feeding function, this online automated optical inspection machine can increase the inspection volume. Comparing to the off-line model, it also has a higher PCB height that is aimed at improving component applicability.

Feature

Option

- High-resolution Telecentric Lens: An optional telecentric lens with high resolution, unique parallel light design that the PCBA tilted or tall components can be distinctly displayed.

-

Large Bar-code Recognition System: When the bar-code exceeds a single FOV, the bar-code divided by the FOV can be spliced into a complete bar-code.

The flying FOV is extremely difficult to recognize when facing a large bar-code, and the machine can handle without any pressure.

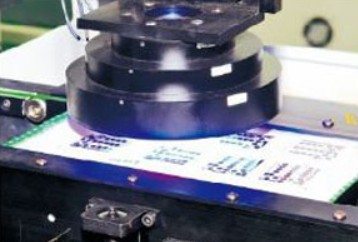

1. Five Million Pixel Industrial Camera

- The machine is equipped with an ultra-high-resolution industrial camera, which can take a clear and high-quality picture of the PCB board. It efficiently ensures the stability of image shooting when the machine is working.

2. Precise and Reliable Mechanical and Electrical Functions

- The motion system uses servo drives, precision grinding, and screw rods to control the motion structure, with extremely high precision and reliability, and reliable electrical performance

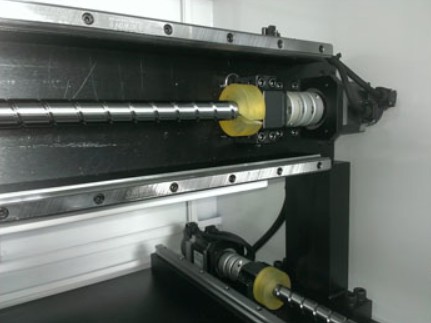

3. X, Y-axis Driving Parts

- The X, Y-axis both adopt the high-precision screws and motors to drive, ensure the stable and reliable moving performance.

4. Automatic Splint

- The splint positioning and adjustment is quick and automatic.

5. Original Whole Board Matching Function

- Whole board inspection, seamless docking, precise positioning, splicing the whole board picture into a single picture, it can detect throwing materials, multiple pieces, tin balls, gold finger scratches, and bad plates on any position of the PCB board.

6. Flexible Mobile Maintenance Station and SPC Query Terminal

- Using mobile terminals under the wireless network, it is possible to set up workstations at any position in the workshop, adopting one-to-many mode, and confirming the detection data of multiple online machines through a maintenance workstation, which has achieved the goal of saving personnel.

- Well-designed SQL data system, the SPC data reported through the pie chart and histogram, which is very convenient for customer process analysis and quality improvement.

7. Programming System

- Intelligent and fast programming, intelligent algorithm, no need for manual intervention, easy to learn, high detection rate, low error rate.

8. GPU Independent Hardware Processing Images

- It adopts the GPU independent hardware processing images, while CPU processing non-image computing, so as to balance the efficiency of the computer system.

9. Convenient and Practical Offline Programming Software

- Adopt OLP Offline programming software, which is easy and practical.

- Real-time PCB genuine image shooing system, enable to be stored in full memory, which also ensures high-efficient programming under circumstances of either online or offline.

Keywords:

SMT Machine Line, SMT Machine Production Line, Manual Stencil Printer, Solder Paste Stencil Printer, Oven Reflow SMT, Table Top Reflow Oven, Wave Soldering Machine Selective, Sumsan PICk And Place Machine, MagnetIC PICk And Place Tool, PICk And Place Production Line, Cheap SMT PICk And Place, Hanwha SMT PICk And Place, SMT PICk And Place Parts, High Speed PICk And Place, SMD Soldering PICk And Place, PICk And Place Parts Juki, PICk And Place Machine W2, Vaccum PICk And Place Machine, Conveyor Type PICk And Place, PICk And Place Two Axis Boxes, Coating Line, UV Coating Production Line, SMT Conformal Coating Line, Cy PCBA Conformal Coating Line, PCB Router Bit Rcf, PlastIC PCB Router Enclosuret, Mini CNC PCB Router, Mini CNC Router Para PCB

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com