Offline SMT AOI

From: Author:Offline SMT AOI Publish time:2021-09-15 11:00 Clicks:0

Offline SMT AOI

Basic Description

The latest model of off-line AOI can inspect a large range of items, and the minimum component can reach 0201 chip. Besides, it equipped with a wide covered of lighting sources with a high-pixel industrial camera to make a high-quality image.

Also, it can reach a maximum moving speed of 830 millimeters per second with a positioning accuracy of smaller than 8 microns, which ensures its high volume of production capacity.

Then, with an upgraded software system, it can be operated easily and improve the programming method, making the working process more intelligent and flexible.

Feature

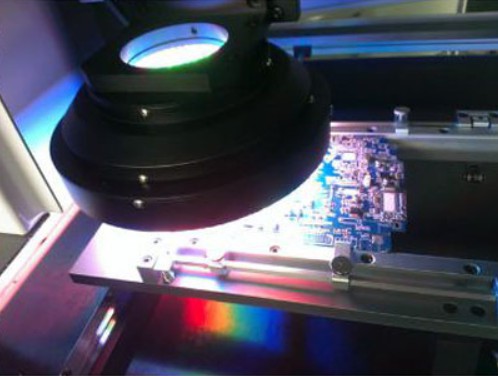

1. High-Pixel & High-Speed Industrial Camera

- High resolution, full-colored, and high speed industrial digital camera is equipped. Owning a pixel of five million and an optional pixel of 16 or 20 million, which ensures high quality, reliable image shooting and restores a real and natural image effect.

2. Multi-colored LED Light Sources

- Adopting multi-angle circular tower-shaped high-brightness long-life LED light source, with excellent positioning ability, can adapt to various PCB boards, including the situation without MARK point.

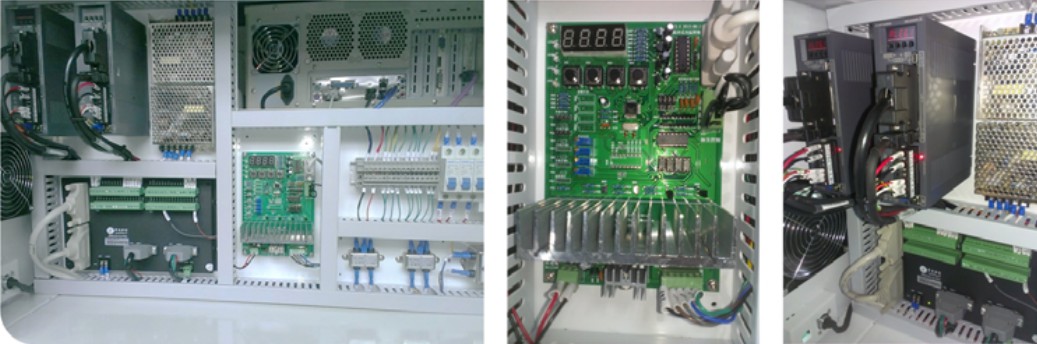

3. Internal Structure of Equipment

- As the below photo shown, all of Imported electric components are used into for assembly of this SMT AOI, which ensures high stability and performance.

4. Multi-modes Working Station

- Using only one maintenance workstation to check the inspection data from multiple online machines, and the defect details are reported clearly.

5. Emergency Stop Button

- When there are any emergency situations that happened during production, it is effective to make the machine stop immediately.

Specification

| Model | Off-line AOI |

|---|---|

| Application | Visual inspection for small PCB or components |

| Program mode | Manual programming |

| Inspection Items | Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. |

| Inspection Items | Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. |

| Calculation Method | Machine learning, color calculation, color extraction, gray scale operation, image contrast |

| Inspection Mode | Optimized inspection technology covering the whole PCBA board |

| SPC Statistics Function | Fully record the test data and make analysis, with high flexibility to check production and quality status |

| Component Angle | Support 0-359 degree angle of rotation£¬minimum angular distance 1 degree angle |

| Minimum Component | 0201 chip, 0.1x0.1mm |

| Camera | 5 million pix full color high speed industrial digital camera , 20 million pix camera optional |

| Lens Resolution (Micron) | 10/15/18/20/25, support customization |

| Lighting Source | Self-configurable ring stereo multi-channel color light source, selection depending on application, RGB/RGBW/RGBR/RWBR, coaxial light source or large light source optional |

| CPU | Intel i7, or same level |

| RAM | 8GB |

| SSD | 128G |

| OS | Win 7, 64bit |

| Monitor | 22inch,16:10 |

| Language | Chinese/English optional |

| Access Control | Administrator, programmer, operator 3 levels access control. |

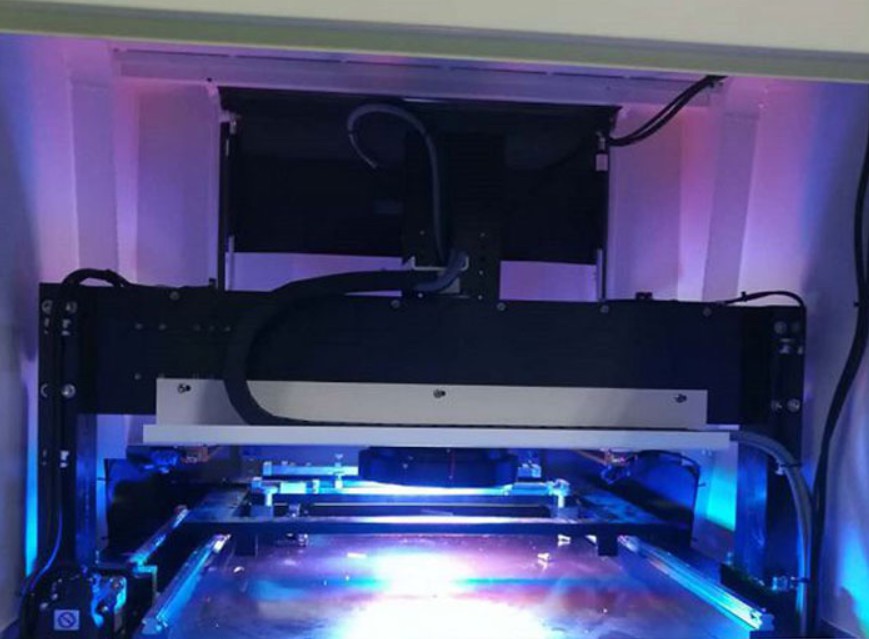

| Moving and Inspection Mode | Automatic feeding board, step motor driving PCB to the inspection position under camera light source, camera takes a FOV image to detect |

| PCB Dimension | 10x10-120x120£¬ can be customized |

| PCB Thickness | 0.3-5.0mm |

| PCB Weight | Max£º3KG |

| PCB Bending | Less than 5mm or 3% of PCB Diagonal length |

| PCB Component Height | Top£º30mm£¬Bottom£º80mm. Adjustable, can be customized base on request |

| XY Driving System | Step motor, precise driving system |

| XY Moving Speed | Max£º500mm/s |

| Power | AC220V£¬50/60Hz£¬0.8KW |

| Environment Temperature and Humidity | 10-35 degree celsius, 35-80£¥ RH (non condensing) |

| Safety Standard | CE safety standard |

| Optional Configuration | Maintenance station, offline programming system, SPC servo, bar code system, MES interface |

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

SMT Line PCB, SMT Full Line, Dual Squeegee Semi-AutomatIC Stencil Printer, Desktop Stencil Printer SMT AutomatIC, Reflow Oven Profiler, Manual SMT Reflow Oven, Wave Soldering Machine Nozzle, Wave Soldering Machine With Flux, Hanwha PICk And Place PCB Machine, PICk And Place Machine 2 Head, Vaccume SMD PICk And Place Machine, SMD PICk And Place Machine, Vision Camera SMT PICk And Place, PanasonIC PICk And Place SplICing Tape, PICk And Place Machine For Packaging, DIP Capacitor PICk And Place Machinery, Conformal Coating Machine Selective, LED Shell AutomatIC Coating Line, PCBA Conformal Coating Line, Desktop PCB Router Machine, Router Power Backup PCB, CNC Router PCB Board, CNC PCB Router Drill