Infrared reflow oven VS Convection reflow oven VS Nitrogen reflow oven

From: Author:Infrared reflow oven Publish time:2021-09-14 15:08 Clicks:0

Infrared reflow oven VS Convection reflow oven VS Nitrogen reflow oven

So, What is the difference between these kinds of reflow oven?

2.1 Definition

- The Infrared reflow oven:

Infrared reflow oven usually is small-sized. Its working principle is that 80% of the heat energy is emitted in the form of electromagnetic wave – infrared ray, the temperature of solder joints increases after infrared radiation, then complete the welding process.

IR reflow oven working principle

We can describe its progressive division as near-infrared ray (0.72-1.5 μ m), mid-infrared ray (1.5-5.6 μ m), far infrared ray (5.6-1000 μ m).

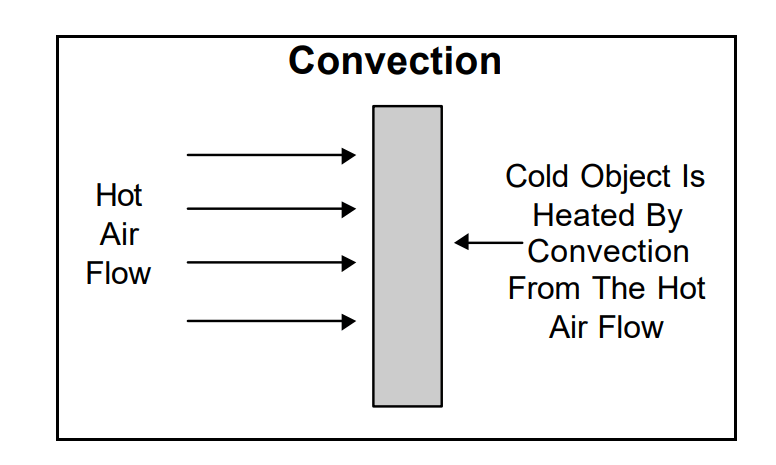

- Convection reflow oven:

Nowadays, forced convection reflow is the desired technique of SMT reflow soldering of surface mounted components to a printed circuit board (PCB), and you could found the method regarding how to wrok as the below image shown.

Convention reflow oven working principle

The oven is generally separated into zones where every sector independently managed to optimize the thermal profile of the procedure sector of the oven.

Convection reflow oven 10 Zones –

Nitrogen reflow oven

The nitrogen reflow oven has one distinct feature, during the production it is to fill nitrogen inside the oven.

Why do you like this?

The purpose is to prevent air from entering the reflow furnace and prevent the oxidation of component feet in reflow welding.

Especially, nitrogen reflow welding is mainly to enhance the welding quality, so that the welding occurs in the environment with little oxygen content (100 ppm), which can avoid the oxidation of components.

Therefore, we should pay attention to ensure that the lower the oxygen content during the production.

2.2 Advantage and disadvantage

- Advantage and disadvantage of the Infrared reflow oven:

Each coin has two sides, hence, the infrared reflow oven also has both advantages and disadvantages, please check the details in the following contents.

Just as its name implies, infrared reflow oven uses infrared ray as its heating source

Advantages: continuous, good heating effect, wide adjustable temperature range, less solder spatter, less reflow soldering and continuous welding;

Disadvantages: Different materials on the circuit board lead to different heat absorption and difficult temperature control. Also the color of the material will affect the heating effect a lot and lead the gap of the difficult temperature control.

- Advantage and disadvantage of the convection reflow oven:

High temperature air circulates in the reflow oven.

Advantages: hot air reflow welding heating uniform, easy to control the temperature;

Disadvantages: it is easy to cause oxidation of components, and strong wind may cause displacement of components.

- Advantage and disadvantage of the nitrogen reflow oven:

Advantages:

① greatly prevent the reduction of oxidation during component welding

②improve the wetting force and speed up the wetting speed

③can reduce the production of solder balls, avoid bridging, and achieve higher welding quality

Disadvantages:

①high price for nitrogen, terrible for the environment.

②Increase the chance of tombstones

③Enhanced wick effect

Nitrogen reflow oven is a very good choice for the following situation:

- OSP surface treatment double side reflow welding plate is suitable for nitrogen.

②Parts or circuit board can be used when tin eating effect is not good

③After the use of nitrogen, it is necessary to pay attention to whether the bad tombstone is increased, and also check whether the soldering foot of connector is too high?

Keywords:

LED Bulb Assembly Line Machine, LED Lamp Line Assemble, Solder Paste Screen Printer, Solder Paste Printer Line, Reflow Oven 2520, Oven Reflow, Wave Soldering Machine Desktop DIP China, Laser Coding Machine SMT Assembly Inline, SMT YSM20R PICk And Place Machine, SMT Component Carrier Tape Packaging Machine, SMT PICk And Place Machine Benchtop, SMT Drill Machine PrICe In Pakistan, AutomatIC SMT Selective Coating Machine, PCB Belt Conveyor, PCB Assembly Conveyor Table, PCB Flipper Inverter Conveyor, SMT Screening Conveyor PCB, SMT Screening Conveyor, Laser PCB Separator, Aurotek PCB Separator

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com