What is A Reflow Soldering oven?

From: Author:Reflow Soldering oven Publish time:2021-09-14 15:05 Clicks:0

1. What is A Reflow Soldering oven?

1.1 Background & Definition

A Reflow oven is a machine used primarily for Reflow soldering of surface mount electronic components to printed circuit boards (PCB).

Generally, it is used in the assembly of a hybrid integrated circuit board. Most of the components are chip capacitor, chip inductor, mount transistor, and two-transistor.

1.2 Working Principle

As one of the three main machines in the SMT line. It working principle is as the following:

Always, it locates after the pick and place machine, and solders the PCB board and component with heating and melting, at last cool the solder to link the PCB board and component together.

With the development of SMT technology and the emergence of SMC and SMD, Reflow soldering technology and equipment as parts of SMT technology have been developed accordingly, and its application has become more and more extensive, almost in all electronics product fields.

Technically, Reflow is to realize the mechanical and electrical connection between the solder end or pin of the surface assembly component and the PCB pad by remelting the paste solder allocated to the PCB pad in advance.

Reflow soldering relies on the effect of hot airflow on the solder joint, and the soldering flux reacts physically under the fixed constant excessive temperature air go with the drift to reap to achieve SMD welding;

Therefore, it is called “reflow soldering”, because the gas circulates in the welder to generate high temperature to achieve the welding purpose.

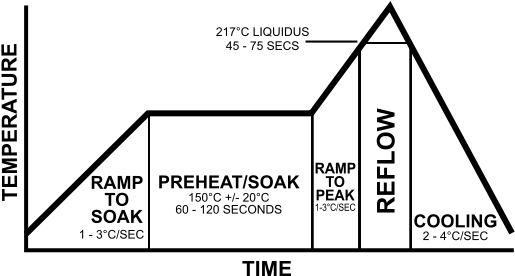

1.3 Working Process

Reflow oven soldering process

- When the PCB enters the heating zone, the solvent and fuel are inside the solder paste evaporate. At the same time, the flux in the solder paste moistens the pad, component end, and pin. The solder paste softens, collapses, and covers the pad, isolating the pad and component pin from oxygen.

- When PCB enters the insulation area, the PCB and components are fully preheated to prevent PCB and components from being damaged due to PCB suddenly entering the welding high-temperature area.

- When the PCB enters the welding area, the temperature rises hastily to make the solder paste melt. The liquid solder can wet, diffuse, diffuse or reflow the solder pad, component end and pin of PCB to form a solder joint.

- PCB enters into the cooling area to solidify the solder joint; reflow welding is completed.

1.4 Types of the Reflow soldering oven

- Types base on the zones

Usually, the length for each soldering zone is about 45-50cm, the quantity for the soldering zone is from three to fifteen or even more.

Furthermore, for the function of the soldering zone, reflow welding has at least three temperature zones, namely the preheating zone, welding zone and cooling zone.

Many usually exclude the cooling zone when calculating the temperature zone, that is, only the heating zone, heat preservation zone, and welding zone.

- Types base on the working technology

There are many types of reflow soldering oven according to different working technology, but we just list three main types among it in the following, please have a look:

- Convection reflow oven

- Nitrogen reflow oven

- Infrared reflow oven

- Types base on the Shape

①Bench type reflow oven is suitable for small and medium-sized PCB assembly production with stable performance and economic price of highly flexible production arrangement.

②Vertical reflow soldering oven is applicable for different kinds of production demands, especially for mass production.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

LED Bulb Assembly Line, LED Bulb Machine AutomatIC Assembly Line, Solder Paste Printer Fully AutomatIC, Solder Paste Printer PCB, Small Reflow Oven, Reflow Oven Rails, Wave Soldering Machine For Large Parts, SMT PICk And Place Machine Set, SMT PICk And Place Machine Oven, SMT Mounting Machine For LED Bulb, Full AutomatIC SMT PICk And Place Machine, Multi-Function SMT AutomatIC Labeling Machine, SMT Unloader New Type, Equipment PCB Conveyor, PCB Multi Rack Loader, Loader PCB, Automat PCB Loader, PCB Drop Loader, SMT Small PCB Loader, Loaders And Unloaders PCB, PCB Inverter Conveyor, PCB Buffer Conveyor