Why Manufactures are Still Using Electrolytic Capacitors in Computer Mother Boards

From: Author:Mark Hardy Publish time:2021-09-13 15:03 Clicks:0

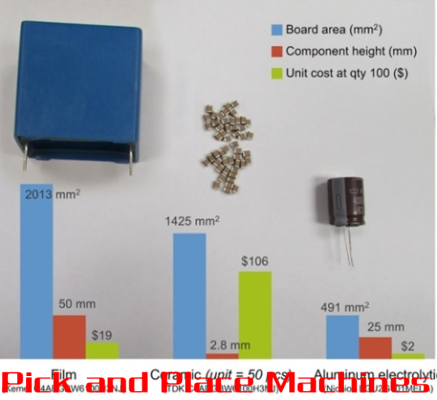

This poses a problem for electronics manufacturers because inserting leaded electrolytic capacitors is a much different process than placing surface mount components. After the surface mount process, the PCBs must be processed on a slide line where assembly workers insert the leaded electrolytic capacitors into the PCB, then use a wave soldering pot to solder the components to the board. This extra process not only adds time, but also cost to the manufacturing of the product.

To help reduce manufacturing costs, a standard radial machine can be used to insert the leaded electrolytic capacitors. Typical spans of leaded electrolytic capacitors used in computer Motherboards are 2.5mm, 3.5mm and 5.0mm. However, many radial insertion machines support only 2.5mm and 5.0mm spans, prohibiting them from handling 3.5mm spans. This limitation can lead to selective automation, which will reduce the ROI (Return on Investment) for investing in a radial insertion machine.

I.C.T Instruments has addressed this issue with the latest tooling enhancement for its Radial 88HT insertion machine. The new tooling supports 2.5mm, 3.5mm and 5.0mm component spans, enabling automation of a full range of leaded electrolytic capacitors for computer motherboards and other applications. By automating these components, manufacturers can benefit through increased output and superior yields, delivering a fast and significant ROI.

Neil Ross, Marketing Manager of Through-Hole products at I.C.T Instruments; results-oriented with more than 30 years of experience in the electronics/semiconductor industries.

SMT Line Memory, SMT Ai Line, Stencil In For Printer, Solder Printer, Reflow Oven Miner, Nozzle Wave Soldering Machine, Automatic SMT Terminal Insertion Machine For Electronic Components, Pick And Place Head, Precision Pick And Place, Pick And Place Mache, Pick And Place Machine 4Head, SMD LED Pick And Place, 3D AOI Inspection, AOI Machine Price, Automatic Optical Inspection System, Automated Optical Inspection Equipment, Screw Driver Robot, Desktop Locking Auto Fastening Auto-Screwdriving Machine Automatic Fixing Screw Robot