OVERVIEW

High quality heavy double hook titanium finger ,V and L type is optional

High-precision, automatic spray fluxing system

Spraying evenly and customized flux recovery system

Standard with 3 hot air bottom preheating zones

Standard with simple center support system on solder pot, it is possible to adjust the position of the support point

Top and bottom cooling system after soldering

MAIN FEATURES

THE FLUX SPRAYING SYSTEM

The Flux Spraying System is perpendicular to the PCB, so it Spread more even on PCB and Enhance flux penetrating property to the holes Improve the adhesiveness of the solder metal Effectively reduce operating cost.

MODULARIZE SOLDER POT

10mm thickness casting iron solder pot, No easy to deform when heating Perfect contact with heater for more uniform heating Used graphite for insulation for anti-moisture and anti-corrosion The pot is Ceramic coating for a smoother surface, prevent corrosion, longer life time.

CONVEYOR FINGER

Standard equipped with strong conveyor finger, hardly get bent. Good for both bare PCB and also 5kg weight carrier. Specially designed for heavy load carrier.

USER FRIENDLY INTERFACE

Industrial PC and Siemens PLC for controlling system, English interface. Can stock numerous groups parameters. Direct input target temperature into the program Display actual temperature.

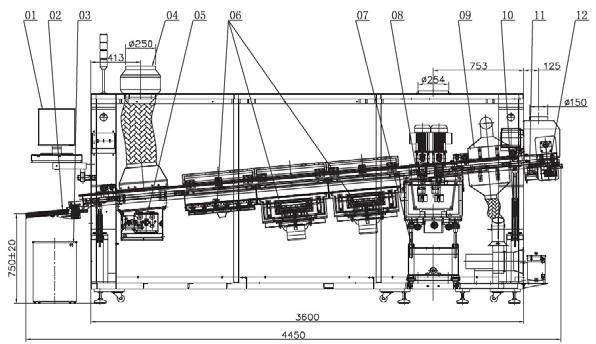

- 1. LCD

- 2. Buffer system

- 3. Flux auto-supply system

- 4. Exhaust fan

- 5. Flux spray system

- 6. Pre-heater

- 7. Solder pot lifting unit

- 8. Dual wave Solder pot

- 9. Cooling system

- 10. Angle adjustment controller

- 11. Finger cleaning system

- 12. Conveyor system

Keywords:

SMT LED Assembly Line, LED Light For Assembling Line, Dek SMT Solder Paste Printing Machine, Reflow Soldering Oven Machine, Fully AutomatIC Wave Soldering Machine, LED SMT Machine, SMD PICk And Place, StICker Placement Machine, Samsung SMT Machine, SMT Machine 3 In 1, AutomatIC LED Bulb And SMT PICk And Place Machine PrICe, LED PICk And Place, UltrasonIC Cleaner PCB Board, Liquid Cleaner PCB In UltrasonIC Cleaner PCB, PCB UltrasonIC Cleaner, PCBA Assembly ServICe UltrasonIC Cleaner

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com