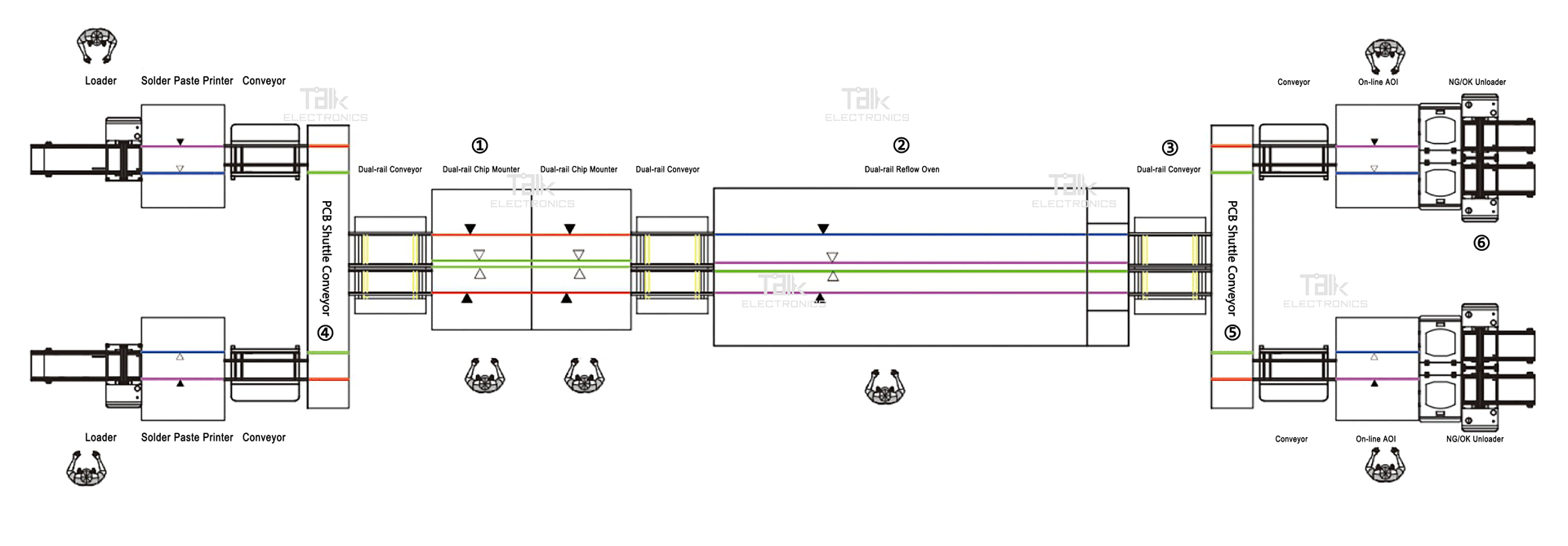

Two-to-One Line With Dual-rail Pick and Place Machine Layout

This layout is designed based on the ①dual-rail chip mounter and ②dual-rail reflow oven and comes with three related ③dual-rail conveyors for linkage. Also, additional combination of production line which including these machines:

Loader, Solder Paste Printer, Conveyor, ④PCB Shuttle Conveyor, ⑤PCB Shuttle Conveyor, Conveyor, Online AOI, ⑥NG/OK Unloader.

The advantage of this layout is that it doubles the production capacity by adding another SMT assembly line. Also, it saved space due to the use of PCB Shuttle Conveyor, dual-rail pick and place machine, dual-rail reflow oven.

Click The Image To Zoom In

①Dual-rail chip mounter is used for dual-rail production which double the mounting speed of PCB board, which Electronics can offer the same dual lane chip mounter such as Juki RX-7R model or Samsung SM471PLUS.

②Dual-rail reflow oven is used for double the soldering capacity of PCB board, which Electronicstalk can provide the machine with optional dual-rail such as the RO-1000.

③Dual-rail conveyor is used for delivering of PCB board from two lanes onto the next machine. And Electronicstalk can provide this kind of machine as well.

④PCB Shuttle Conveyor is used for redirecting PCB transmission flow by combining two SMT line into one dual-rail production line. Correspondingly, the PCB Shuttle Conveyor Electronicstalk offers can be customized by traversing distance.

⑤PCB Shuttle Conveyor used here is for separating the dual-rail production line into two single lines.

⑥NG/OK Unloader is used for detecting the good or bad board in the last step of the SMT line after the AOI inspection process. The same product that Electronicstalk can provide is the NU series of models.

Keywords:

Production Line LED Lamp Assembly, LED Bulb Production Line Assembly Machine, Screen Frame For Solder Paste Printer, Semi-Auto Solder Paste Printer, SMT Reflow Oven, 9 Zones Reflow Oven, Wave Soldering Machine Desktop, SMT Reel Scrap Cutting Machine, LED SMT Terminal Cutting Machine, SMT Ai Glue Dispensing Machine, SMT LED Lens Feeder Machine, PICk And Paste SMT Machine, Make Stancil Machine For SMT, PCB Board Shuttle Conveyor, PCB Handling Conveyors, PCB Belt Conveyors, SMT PCB Conveyor, PCB UV Conveyor, Assembly Heating PCB Separator For Mobile Ipad

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com