PCB Pick And Place Machine

Basic Description

The number of Spindles for PNP-580 can be 8 spindles, which makes it own a higher placement speed than the PNP-560 with number of 6.

As the competitive models with the same production capacity as the other brands such as Samsung 481PLUS.

Moreover, as compared the stability to the Samsung 481PLUS, the PCB pick and place machine can perform without any stopping issues that has been proved by so many customers all over the world.

Feature

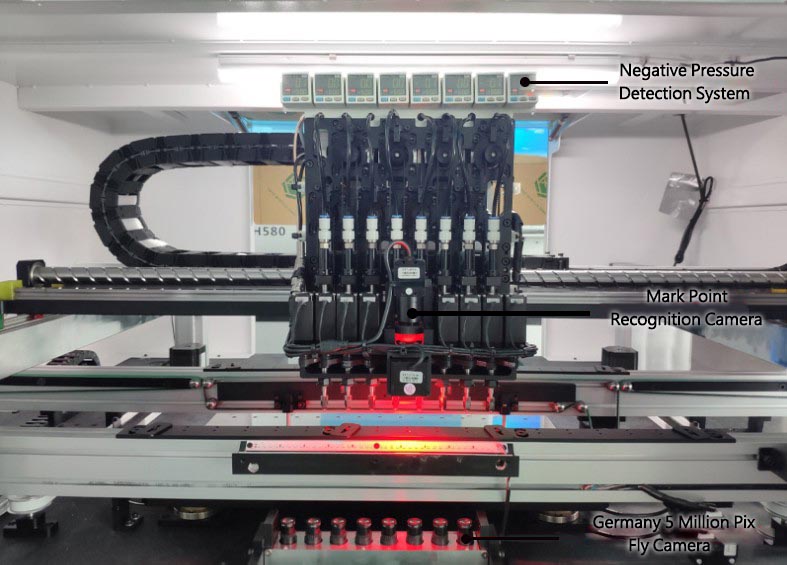

1. High-Efficient Visual System

- Imported negative pressure detection system is used to accurately detect the components, effectively preventing the component leakage and dumping issues.

- Mark point recognition camera is applied, ensures the component quick recognition and precision positioning.

2. Panasonic Servo Motor

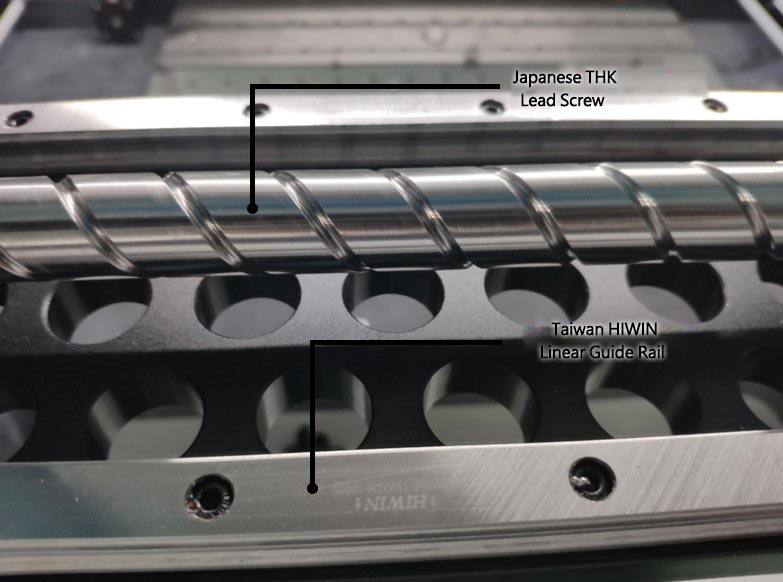

- Driven by Japanese Panasonic servo motor widely used in imported placement machines, ensures the X/Y axis high precision motion and stable mechanical performance.

SM482 Panorama View

3. Fly Camera Origin From Germany

- Equipped with 8 sets of Germany Fly Camera with 5 million pix, ensures a high precision of component recognition and enable to realize fully high-speed pictures taken without missing and stopping during the process, which also dramatically improved the placement speed.

5. High Quality Yamaha Nozzles

- Using the same nozzles as Yamaha, it owns an excellent quality and reliable performance during the picking process. Since this compatible design, it is more flexible and convenient for daily use.

Specification

| Product Name | PNP-580M | PNP-560M |

|---|---|---|

| PCB Size | L600xW400mm (Max. Length enable 1200mm) | L600xW400mm (Max. Length enable 1200mm) |

| Max. Moving Range | X-axis: 600mm, Y axis: 400mm | X-axis: 600mm, Y axis: 400mm |

| Number of Spindles | 8 spindles | 6 spindles |

| Z-axis Max. Moving Range | 12mm | 12mm |

| Optimal Placement Speed | 40,000CPH | 30,000CPH |

| Typical Placement Speed | 13,000-26,000CPH | 10,000-23,000CPH |

| Placement Accuracy | +/-0.05mm | +/-0.05mm |

| Positioning Method | MARK point camera + 6 sets Sony visual camera position + 1 set industrial camera | Same As Left |

| Applicable Components | From the tiny chip of 0402 to resistor and capacitor parts and all kinds of LED chips 3528, 5050, meanwhile meet placement requirements of SOP, SOT, power driver, control board, etc. And compatible with various of high power chips. | Same As Left |

| Types of Production | LED tube light, soft LED strip light, power supply driver, fence light, display module, switch, display screen and other LED application products | Same As Left |

| Programming Method | Automatic visual camera positioning programming | Same As Left |

| Belt Type Feeder | 8mm, 12mm, 16mm, and 24mm | Same As Left |

| Feeder Capacity (8mm standard) | 30 slots | 30 slots |

| Operating System | WINDOWS7 | WINDOWS7 |

| Compressed Air | 0.55MPA | 0.55MPA |

| Power Supply | 220V, 50Hz, 2.0KW | 220V, 50Hz, 2.0KW |

| Major Components | ||

| Flexible Cable | Igus | Germany |

| Servo Motor | Panasonic | Japan |

| Screw Rod | THK | Japan |

| Guide Rail | Hiwin | Taiwan |

| Vacuum System | Vacuum Pump | Germany |

| Z-axis Motor | Shinano | Japan |

| Inductive Switch | Panasonic | Japan |

| Negative Pressure Gauge | Panasonic | Japan |

Dimension

| Dimension (LxWxH,mm) | 1300x1300x1450 |

|---|---|

| Weight (kg) | 1200 |

Keywords:

SMT Line PCB, SMT Full Line, Dual Squeegee Semi-AutomatIC Stencil Printer, Desktop Stencil Printer SMT AutomatIC, Reflow Oven Profiler, Manual SMT Reflow Oven, Wave Soldering Machine Nozzle, Wave Soldering Machine With Flux, Hanwha PICk And Place PCB Machine, PICk And Place Machine 2 Head, Vaccume SMD PICk And Place Machine, SMD PICk And Place Machine, Vision Camera SMT PICk And Place, PanasonIC PICk And Place SplICing Tape, PICk And Place Machine For Packaging, DIP Capacitor PICk And Place Machinery, Conformal Coating Machine Selective, LED Shell AutomatIC Coating Line, PCBA Conformal Coating Line, Desktop PCB Router Machine, Router Power Backup PCB, CNC Router PCB Board, CNC PCB Router Drill

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com