Basic Description

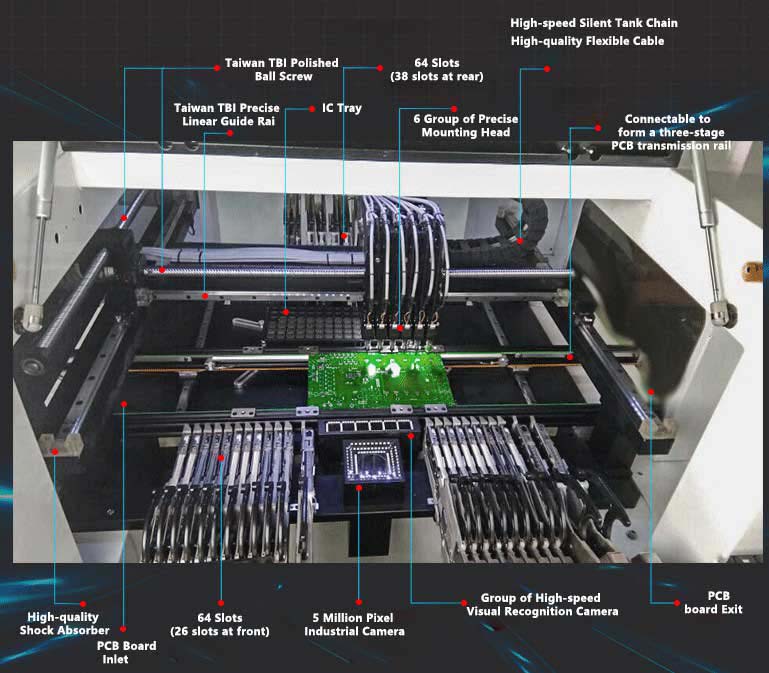

It is the newly launched model that is truly suitable for mid-sized enterprises. Besides, it is a stable, reliable, cost-effective multi-functional placement machine. And own the applicability to stably and accurately mount common chips of 0402, 0603, 0805, 1206, 1210, and LED3528, LED5050 packaged components, diodes, triode SOT, etc..

This low cost pick and place machine has completed the ultimate test and officially launched into the market in batches, equipped with high-end configuration, its performance is stable, and the operation is simple and easy to understand. In one word, It is a cost-effective and genuine full-automatic pick and place machine.

Feature

1. Hardware Core Parts

- The core parts of this machine are high-quality and mostly imported from well-known brands all over the world, which ensures a reliable and stable working performance with long service life.

2. User-friendly Outlook Design

- This low cost pick and place machine entirely take the scientific design from the outside to the interior side which help the operator easy to control any of the parts.

3. Operating System

- Equipped with standard computer monitor mouse-support Windows 7 system, humanized operating interface, support visual editing process, PCB file importing etc.

4. Automatic Board Alignment System + 64 Feeder stations

- After printing the PCB board, it can be directly put into the guide rail to automatically feed the board, achieving automatically alignment and placement.

- With large feeding station, it can support 64 groups of feeding stations at the front and rear side, standard IC tray, tube mounted chip vibration, three tube sizes can be adjusted at will.

5. Synchronous Recognition of Six Cameras

- Added 6 industrial-grade fast recognition cameras, which enable simultaneously recognition and effectively ensure placement speed and accuracy. The place placement efficiency doubled on the original basis rate almost.

6. Panasonic Servo System

- Adopting with imported servo system from Panasonic, which have high precision, strong stability, never lose step pitch. The system can guarantee 24 hours stable placement.

7. High Pressure Wear-resistant Tank Chain

- Using the same type of tank chain as imported machines, can withstand pressure up to ten millions of times.

8. High Precision TBI Guide Rail

- Adopting with the high precision TBI guide rail from Taiwan, can effectively guarantee the mounting accuracy of 0201 and BGA components.