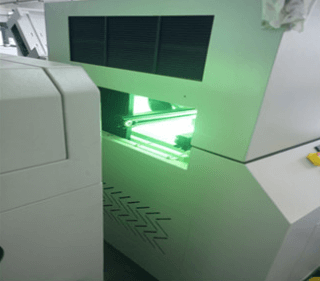

UV Curing Oven

Basic Description

The UV curing oven is also called UV furnace, which “UV” is the abbreviation of ultraviolet light. And “curing” refers to the process of converting a substance from a low molecule to a polymer. The UV curing oven is an equipment that obtains a coating film that can also be cross-linked through the rapid polymerization of a monomer/oligomer mixture.

Thus, the UV curing generally refers to the curing conditions or requirements of coatings (paints), adhesives (glue) or other potting sealants that need to be cured with ultraviolet rays, which is different from heating curing, bonding agent (curing agent) curing, natural curing, etc.

Feature

1. Light Source System

- The equipment carries 2 sets of electronic dimming light sources at the same time, and the UV light intensity can be adjusted infinitely.

2. Conveyor System

- Stainless steel chain conveyor, the effective width is 50-450mm, the width can be adjusted automatically.

- The conveying speed can be regulated by the touch screen, and the conveying drive mode is driven by stepper motor.

3. Temperature Alarm System

- Use of PLC and touch screen control, with independent temperature controller alarm, double over temperature protection.

3. Temperature Alarm System

- Use of PLC and touch screen control, with independent temperature controller alarm, double over temperature protection.

4. Detection Function

- The equipment has the function of detecting the entrance and exit board, and the amount and conveying condition of the inner board of the equipment can be observed at any time.

5. Automatic Opening Function

- Hand-operated lamp lifting method, the device automatically lifts and opens the cover function. It can be observed at any time.

Specification

| Model | UV |

|---|---|

| PCB Transfer Height | 920 +/- 20mm |

| Transportation Speed | 0-3500mm/min |

| Transfer Direction | L to R (R to L) |

| Transmission Motor | Stepper motor + transmission case |

| Delivery Method | Chain conveyor (35B5 extended stainless steel chain) |

| Number of Temperature Zones | 2 zones |

| Temperature of Adjustment Range | WVA, UVB/UVC full range |

| Heating Time | Less than 5 minutes |

| Max. PCB Board Size | W450mm*L450mm |

| Max. PCB Component Height | +/- 100mm |

| Opening Method | Touch screen control |

| Power Supply | AC380V 50HZ, three phrase |

| Total Power | 8KW 14A |

Dimension

| Dimension (LxWxH, mm) | 1800x1080x1300 |

|---|---|

| Weight (Kg) | 490 |

Keywords:

SMT Ai Total Solution Line, High Precision High Resolution SMT Off-Line, Semi-AutomatIC Solder Paste Screen Printing, Stencil Screen Printer, Reflow Oven Cleaner, PCB DIP Soldering Machine, Industrial Camera Vision PICk And Place, Nozzle PICk And Place, PICk And Place Machine Hanwha, Sheet Metal PICk And Place Machine, 8 Head PICk And Place Machine, Neoden3V SMT Machine, Auto OptICal Inspection, Automated OptICal Inspection PCB, SPI Machine In SMT, AutomatIC OptICal Inspection PPT, Robot Lawn Mower PlastIC Screws, Adsorption Double Platform Screw Robot, Desktop Locking Auto Fastening Auto Screw Driving Machine AutomatIC Fixing Screw Robot

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com