Displacement of components after reflow soldering

| Reason: | Defect Elimination method |

| Wrong location | Calibrate positioning coordinate |

| Insufficient amount of solder paste or pressure for positioning | Increase the amount of solder paste, increase the pressure of placing components |

| The flux content in the solder paste is too high, and the flux flow in the reflow process leads to component displacement | Reduce the content of flux in solder paste |

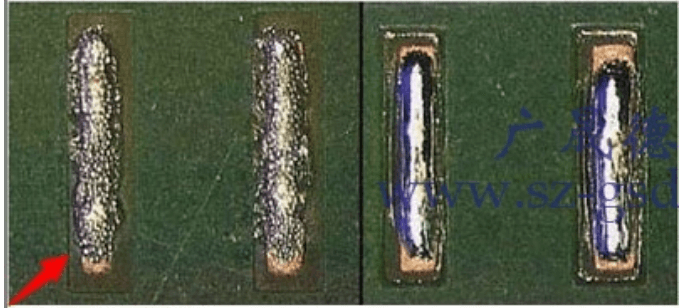

(2)After reflow soldering, solder paste welding powder can’t flow anymore, and it is scattered on the pad in powder form

Solder paste

| Reason: | Defect Elimination method |

| Improper heating temperature | Improve heating equipment and adjust the temperature curve of reflow soldering |

| Solder paste deterioration | Pay attention to the cold storage of the solder paste and discard the hardened or dry part of the solder paste surface |

| Excessive preheating, time or temperature | Improve preheating conditions |

- The reflow solder joint is insufficient and less solder

Solder joint

| Reason: | Defect Elimination method |

| Insufficient solder paste | Enlarge the aperture of wire mesh and leakage plate |

| Poor welding performance of pads and components | Use solder paste or re impregnate components |

| Short reflow time | Longer reflow time |

- Too much solder in reflow solder joint

| Reason: | Defect Elimination method |

| Too large screen or leakage plate aperture | Reduce the diameter of wire mesh or leakage plate |

| Low viscosity of solder paste | Increase paste viscosity |

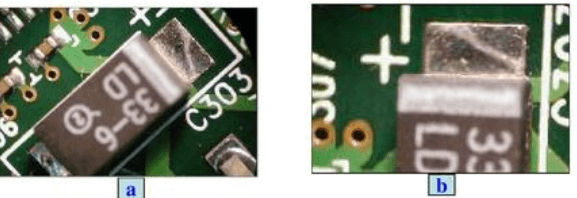

- After reflow soldering, the components are firm, and the “Manhattan” phenomenon appears (“stele”)

Manhattan

| Reason: | Defect Elimination method |

| Displacement of placement position | Adjust the parameters of solder paste printing machine |

| Flux in solder paste makes components float | Use solder paste with less flux content |

| Insufficient thickness of printing solder paste | Increase printing thickness |

| Heating speed is too fast and uneven | Adjust reflow temperature curve |

| Unreasonable pad design | Pad design in strict accordance with specifications |

| Using Sn63 / Pb37 solder paste | Use paste containing Ag or Bi instead |

| Poor weldability of components | Select solder paste with good weldability |

- Solder ball after reflow welding

Solder ball

| Reason: | Defect Elimination method |

| Heating too fast | Adjust reflow temperature curve |

| Solder paste absorbs moisture | Reduce ambient humidity |

| Solder paste is oxidized | Use new solder paste to shorten preheating time |

| PCB pad contamination | Change PCB or increase solder paste activity |

| Too much pressure on components | Reduce pressure |

| Too much solder paste | Reduce the hole diameter and pressure of scraper |

- Faulty reflow

Faulty reflow

| Reason: | Defect Elimination method |

| Poor solderability of pads and components | Strengthen the screening of PCB and components |

| Incorrect printing parameters | Reduce paste viscosity, check scraper pressure and speed |

| Improper reflow temperature and temperature speed | Adjust reflow temperature curve |

- Continuous bridging after reflow

| Reason: | Defect Elimination method |

| Solder paste collapse | Increase the metal content or viscosity of the solder paste, and change the solder paste |

| Too much solder paste | Reduce the diameter of wire mesh or leakage plate, and reduce the pressure of scraper |

| Multiple printing on pad | Using other printing methods |

| Heating too fast | Adjust reflow temperature curve |

Soldering bridge

- Solder paste collapse

| Reason: | Defect Elimination method |

| Low viscosity and poor thixotropy of solder paste | Choose the right solder paste |

| High ambient temperature | Control ambient temperature |

- The reflow solder paste has poor washability, leaving white residue after cleaning

| Reason: | Defect Elimination method |

| Poor wash ability of flux in solder paste | Solder paste prepared with a good washable flux |

| The cleaning agent does not match, and the cleaning solvent cannot penetrate into the pores | Improve cleaning solvent |

| Incorrect cleaning method | Improve cleaning methods |

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

LED Screen Assembly Line, LED Lamp Assembly Line, Printing Stencils, Screen Printing Stencils, LED Special Vacuum Reflow Oven, Batch Benchtop Nitrogen Reflow Oven, Wave Soldering Machine, Laser Coding Machine SMT Assembly, Juki SMT Machine Spare Parts, SMT Light Testing Machine LED, Empty Reel For SMT Machine, SMT PCB Suction Board Machine, SMT Machine For Bar Phones, PCB Chain Conveyor, 1.5M PCB Conveyor, PCB Inspection Conveyor, PCB Stack Conveyor, PCB Assembly Conveyor, Depaneling Machine V-Cut PCB Separator, Soldering Robot, Cheap Soldering Robot, AutomatIC Soldering Robot, Soldering Robot AutomatIC