Scalable size for the application

Scalable Cover Package Design

Common side covers and frame structure

Cross members grow to match application needs

Machine widths from 750mm to 1500mm

Touch screen user interface front (rear optional)

Control Cabinet Flex Mounting

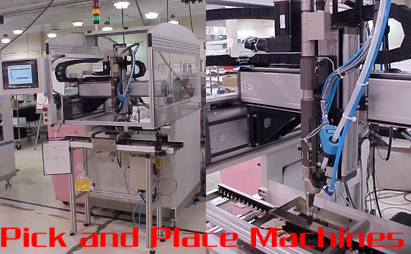

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

More details, please contact us:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etaSMT@foxmail.com

The control cabinet can be mounted on the floor or hanging from the back of the machine

Configuration

Gantry Overhangs Conveyors

Allows for compatibility with wide range of conveyors

Allows for easy installation and relocation

PLC Control

Omron PLC control

Network capable

PC can be easily added for traceability, file storage, or messaging

Head Interface

Same interface as Polaris Multi-process

Any tool created for that interface will be capable of adapting to this cell

Proven Positioning System

NSK Sealed, lead screw drive

Servo Driven X and Y axis offered in multiple lengths

X: 750mm, 1000mm, 1250mm, 1500mm. Y: 800mm

Pneumatic slides available for simple stroke

Combinations of Pneumatic and servo are possible

a2

Polaris Junior Application

1000mm Junior with Screwdriver

This machine is a three axis servo machine

Equipped with a Webber, Electric Screw driver

The conveyor that the customer selected was MagStar

In-Line Press Platform

This application is built on Universal’s press platform

This machine is equipped with a servo press from Schmidt technologies

The press is capable of sensing pressure in 2 oz increments with a maximum of 300lbs

The structure is capable of pressures up to 2000 lbs

1500mm Polaris Junior

This application is built on Universal’s Polaris Junior Platform

The function will be a test handling application

There will be 5 test nests that the machine will have access to load and unload

The stages are micro positioning stages for the test nest

Each stage will precisely position the product using a camera, before applying the probes

SMT Line Manufacture, SMT Plug In Line, Semi-Automatic SMT Stencil Printer, SMT Printer, Desktop Automatic SMT Soldering Machine Desk Reflow Oven, Selective Wave Soldering Machine, SMT UV Curing Machine, SMT Vacuum Suction Machine, Place Machine For SMT, Yamaha YSM20R SMT Machine, SMT PCB Cleaning Machine, SMT Tray To Reel Machine, Inspection Conveyor Belt, Board Cutting Conveyor, Buffer Board, Ng Board Screening Buffer Machine, Conveyor Board PCB Conveyor Driver, Single Sided Conveyor, Edge Chain Conveyor, Connection Station, , Gantry Type Soldering Robot, Robot PCB Soldering Machine