What is ESD?

ESD is a build-up of charges over a specific area without current flow. One of its causes is similar or dissimilar material contacting and separating. As long as this build up continues, the charges will increase until they reach a level that breaks down the strength of an insulator (either material or air). The charge or charges will equalize very rapidly, and the equalization is an uncontrolled discharge called an ESD Event. Lightning is an extreme example of an ESD event.

ESD is not a new problem. Black powder manufacturing and other pyrotechnic industries have always been dangerous if an ESD event occurs in the wrong circumstance. During the era of tubes (AKA the good old days of electronics) ESD was a nonexistent issue for electronics, but with the advent of semiconductors and the increase in miniaturization, it has become much more serious.

ESD comes in many forms; it can be as small as 50 volts of electricity being equalized up to tens of thousands of volts. The actual power is extremely small, so small that there is generally no danger to someone who is in the discharge path of ESD. It usually takes several thousand volts for a person to even notice ESD in the form of a spark and the familiar zap that accompanies it. The problem with ESD is that even a small discharge that can go completely unnoticed can ruin semiconductors. A static charge of thousands of volts is common; however it is not a threat because there is no current of any substantial duration behind it. These extreme voltages do allow ionization of the air and allow other materials to break down, which is the root of where the damage comes from.

Damage to components can, and usually does occur when the part is in the ESD path. Many parts, such as power diodes, are very robust and can handle the discharge, but if a part has a small or thin geometry as part of their physical structure then the voltage can break down that part of the semiconductor. Currents during these events become quite high, but are in the nanosecond to microsecond time frame. Part of the component is left permanently damaged by this, which can cause two types of failures; specifically catastrophic and latent damage.

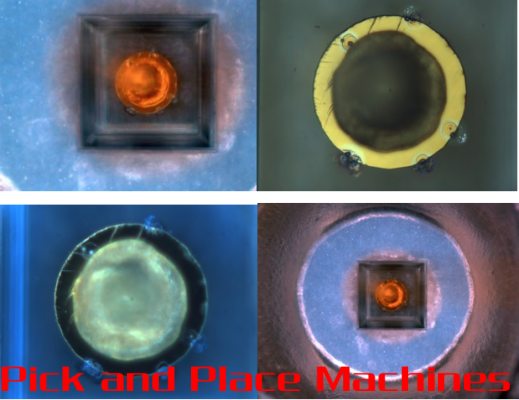

Catastrophic Damage: Once an electronic device is exposed to an ESD event, the device’s circuitry may be permanently damaged causing the device to fail. Usually this can be detected using a basic performance test. The images below of catastrophic ESD damage were provided by Universal Instruments’ Advanced Process Lab who regularly conducts Failure Analysis testing on ESD damaged components. For further information on the APL, visit their website at: https://www.uic.com/solutions/apl

The images below are of a forced 5,000 Watt ESD event performed on an IM LED at Universal’s APL. The pictures are collected from a z-section looking through the lens of the LED directly above the ball bonded die. All four images are of the same sample at different magnifications and illumination techniques. The ESD damage can be detected by looking at the electrical arcing damage surrounding the circumference of the Gold pad on the die surface.

Latent Damage: A device that is exposed to an ESD event may be partially degraded, yet continue to perform its intended function. ESD latent damage may be detectable by its electrical signature but its lifetime behavior is not predictable. *One example can be seen below. Latent damage can result in permanent failure under some stress conditions making the device unreliable.

Latent damage may also allow the problem component to work for hours, days or even months after the initial damage before catastrophic failure. Many times these parts are referred to as the “walking wounded”, since they are working but bad. If these components end up in a life support role, such as medical or military use, then the consequences can be grim.

*Latent damage on a Voltage Regulator, which worked for an hour after the ESD incident.

Ways to prevent ESD Damage:

ESD can be prevented by integrating Electrostatic Discharge Protected Areas (EPAs) into your manufacturing process. The EPA can be a small workstation or a large manufacturing area. The main principle of an EPA is that there are no highly-charged materials in the vicinity of ESD sensitive electronics, all conductive materials are grounded, workers are grounded, and charge build-up on ESD sensitive electronics is prevented. International standards should be used to define a typical EPA and can be found through the International Electro technical Commission (IEC) or American National Standards Institute (ANSI).

ESD prevention within an EPA may include using appropriate ESD-safe packing material, the use of conductive filaments on garments worn by assembly workers, requirement of *wrist straps and foot-straps to prevent high voltages from accumulating on workers’ bodies, anti-static mats or conductive flooring materials to conduct harmful electric charges away from

Fully Automatic Line, LED Line Assemble, Solder Paste Printer Support Frameless Stencil, Semi Automatic Stencil Printer Sp 400V, Nitrogen Reflow Oven, Single And Dual Wave Soldering Machines, SMT Scrap Tape Cutting Machine, LED SMT Terminal Insertion Machine, Automatic SMT Terminal Insertion Machine, Fabrication SMT Machine Metal Fabrication, Desktop PCB SMT Strip Printing Machine, Automated SMT Pick And Place Machine, PCB Conveyor Dryers, PCB Conveyor Chain, PCB Screening Conveyor Mst, PCB Conveyor Roller Chain, Camera Conveyor Inspection, Solder Paste Robot, Parts Solder Robot, Tabletop Soldering Robot, Usb Soldering Robot