The majority of people are not fully clear what Industry 4.0 is all about and afraid to make mistakes when implementing new manufacturing strategies. Many don’t seem to know where to start.

Some think having a robotic manufacturing line means having a smart factory. Wrong. A smart factory comes with a working Cyber Physical System, remember? The industrial robots we see today are far from Artificial Intelligence. It strictly follows the programs set by human; its ability to self-learn and self-adjust is extremely limited.

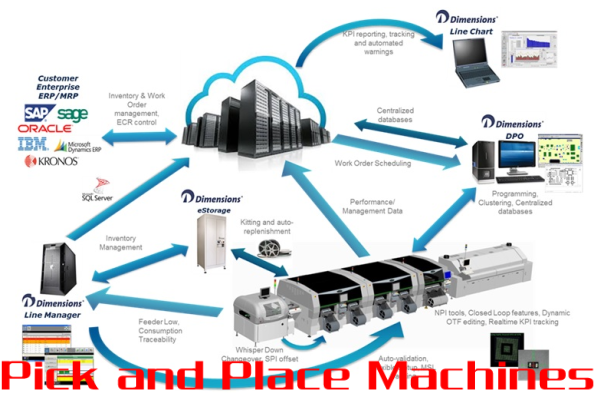

Having a robotic manufacturing line now only indicates an increased level of automation. It is by no means a deliverable under the Industry 4.0 banner; the use of electronics and IT to automate production falls into the deliverables of Industry 3.0. The true market driver for Industry 4.0 is the need for factory to be flexible. It is not a matter of individual process; it is about automating the Industry 3.0 automated processes on a site-wide or even enterprise level. True Industry 4.0 is the actual computerization of an entire factory operation based on a common IoT communication mechanism.

Some companies are having the idea of purchasing an “Industry 4.0 Compatible” or “Industry 4.0 Ready” machine. Sorry, such machines don’t exist at this point. Take SMT industry for example, the key principles of Industry 4.0 for SMT-related manufacturing are not yet in place. There are no standards for even the most basic inter-process shop-floor communication and control that have become dominant.

Let’s look at the term “Internet of Things” closely. For Internet of Things, you need to have “Things” first, so that the “Things” can be connected by the “Internet”. Since we haven’t completely accomplished the goals of Industry 3.0, we should continue automating our production.

Meanwhile, another aspect that we shouldn’t neglect is Big Data analytics. Same as having a long way to go to become a true Smart Factory, analyzing Big Data to make manufacturing predictive is not happening immediately. What we can do now, is the collection of Big Data. It is not just about adding sensors to machines. More importantly, it is about starting considering tomorrow’s partner ecosystem.

Ask: “Which companies are also trying to reach my customers and my customers’ customers? What other products and services will talk to mine, and who will make, operate and service them? What capabilities and information does my company have that they need? How can we use this ecosystem to extend the reach and scope of our products and services?”

Look for software providers, systems integrators and partners so that your Big Data can be used to make your manufacturing mode predictive, your product more compatible and your factory easier to be integrated into the Internet of Things.

It will take some time to reach Industry 4.0, and the road towards that needs to be paved step by step.