How to Solder MEMS Microphones

With more and more home assistants and voice interactive devices appearing in the consumer domain, microphones are being incorporated in more and more devices than ever before in increasingly more compact forms. This has encouraged the emergence of new technologies like the MEMS (microelectrical- mechanical systems) technology and more recently, case mounted versions for improved performance, but this comes at the expense of ruggedness and structural integrity. Subsequently, it is no surprise that these smaller, more fragile packages demand extra care and proactive planning during the production stage.

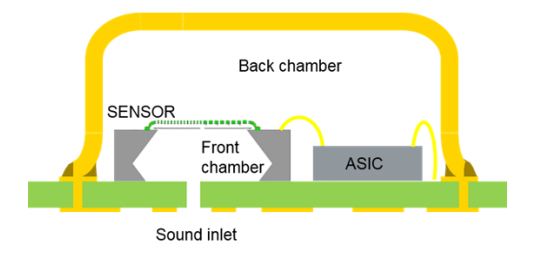

MEMS microphones, also known as a microphone chip, is a miniature SMT acoustic device that picks up sound waves. It typically consists of two parts situated side by side; the ASIC chip and the MEMS acoustic sensor mounted on a PCB board, which is then enclosed within a metal or plastic casing. Sound waves must enter the enclosure to reach the acoustic sensor somehow, so inevitably a physical hole is needed somewhere on the package. This hole or sound port can be located on the top of the package on the enclosure, or on the bottom. If it is located on the bottom, a hole needs to be drilled into the main PCB board as well.

Bottom-port MEMS microphones such as the MP23ABS1 by ST have the inlet located directly below the acoustic sensor which maximizes the size of the back chamber. A larger volume in the back chamber allows the membrane to move more freely and therefore increases the signal to noise ratio (SNR) and improves low-frequency response. Likewise, a smaller front chamber improves high-frequency response by removing the Helmholtz resonance to a higher frequency. This configuration provides optimal performance but comes with a downside.

Top and bottom sides of the MP23ABS1 MEMS microphone by ST

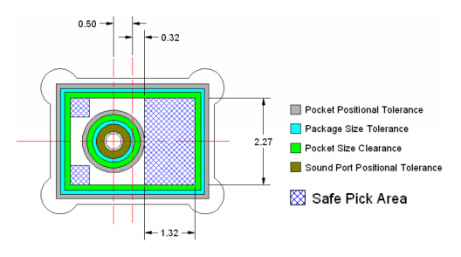

With a typical reflow soldering procedure using an appropriately designed stencil, solder should not find its way into the inlet. Bottom-port MEMS mics can be identified by the characteristic ring-shaped ground pad encircling the sound port. The corresponding opening in the stencil should be designed as follows:

Traditional top-port MEMS mics are the same as bottom-port variants except the hole is placed above the sensor in the enclosure directly. This reverses the two chambers and produces a mic with inferior properties. Some models like the MP34DT01 have the hole located above the ASIC instead to protect the membrane from dust and more recent technologies make the most of both worlds by mounting the sensor and ASIC on the casing itself. These have the improved performance of bottom-port mics without the soldering complications.

By following the above guidelines, the dangers presented by the sound port can be averted. However, as Seeed’s production line engineers discovered, the boards were not out of the woods yet.

In early production runs, an unusually high proportion (around 10%) of mics in the four corner positions completely failed or had poor performance. Post reflow part substitution isolated the problem to the mics and since the failures were almost always located in these four areas, suspicion was directed to the design of the panel.

Location of the four defective mics

Samples of the defective mics were returned to the supplier for professional analysis and the findings confirmed that the inner membranes of the mics were damaged by mechanical stress. Strain gauge analysis verified that the depaneling stage was indeed the most probable point of failure and the cause of the membranes’ rupture.

Component Damage Report

Relocating and reducing the width of the tabs did the trick. Mics highlighted in green.

MEMS microphones have relatively demanding design requirements that should be factored into the PCB and final product design as early as possible. Gasket design and top/bottom configuration may play a big role in determining the position of the mic in the device and may even influence the shape of the product enclosure. Then, it is important to ensure the assembler is aware of the necessary precautions to optimize yield.

Keywords:

SMT Production Line, SMD Production Line, SMT Assembly line, PCB Assembly line, LED Production line, led bulb production line, led display production line, led panel production line, led street lights production line, led strip production line, led tv production line, smartphone smt line, Automatic SMT Assembly line, Semi Automatic SMT Assembly line, electronic production line, JUKI Assembly Line, Samsung Assembly Line, Hanwha Assembly Line, Panasonic Assembly Line, Siemens Assembly Line, FUJI Assembly Line, Yamaha Assembly Line.