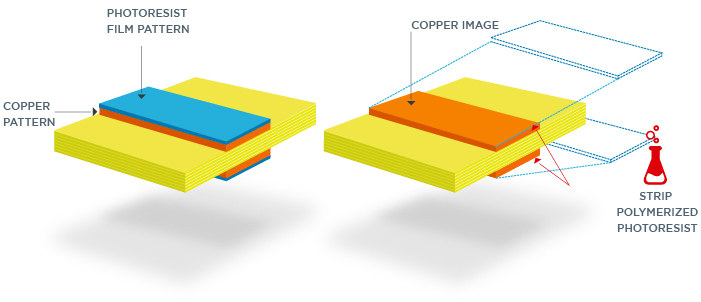

INNER LAYER DEVELOP/ETCH/STRIP

From: Author:INNER LAYER DEVELOP/ETCH/STRIP Publish time:2021-09-17 15:47 Clicks:0

After the inner layer is exposed on both sides it will be processed through a develop/etch/strip line. A DES line is typically a horizontal conveyorized machine approximately 75 feet long. The developer is the first step, the sole purpose of developing is to remove the unpolymerized dryfilm exposing the base copper. The next step is the etcher which dissolves the unprotected copper. The last step is the stripper which removes the polymerized resist using a high pH solution.

AUTOMATED OPTICAL INSPECTION (AOI)

Inner layers are typically inspected by AOI machines. The AOI machine will scan both sides of an inner layer one side at a time, the total process will take several minutes. After scanning each side, the operator can review each of the flagged locations to verify if there is an issue. Once the inner layer has been accepted it is sent to the lamination department.

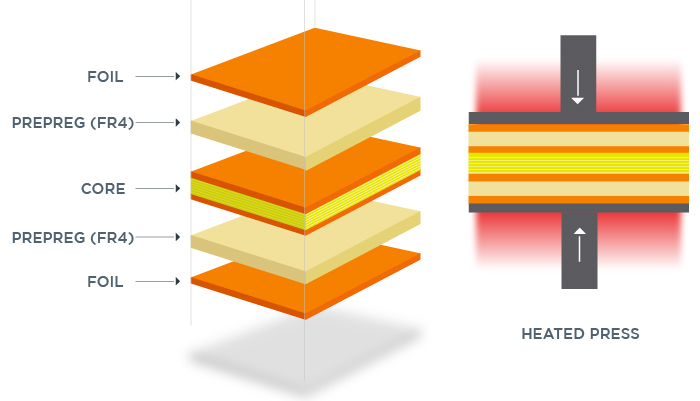

LAMINATION

Prior to lamination the inner layers are processed through an oxide process which alters the copper surface topography in order to increase the bond strength of the prepreg to the copper. The layers are assembled into a stack with prepreg used as bonding sheets and then laminated. The lamination process consists of the panels being bonded together in a vacuum at high pressure and high temperature. Each material has its own unique rheology that requires specific lamination parameters. The key parameters are heat rise, cure temperature, cure time and pressure.

Keywords:

Auto Assembly Line For Big Size TV, SMT Soldering Machine Reflow Oven, Auto DIP Soldering Machine, Tabletop PICk And Place Machine, PICk And Place AutomatIC Machine, PICk And Place Paper Machine, Separator PICk And Place Machine, PICk And Place Compenment Machine, PICk And Place Machine PCBboard, PICk And Place Machine Production, PCB Cutting Machine, PCB Lead Cutting Machine, PCB V-Cut Machine, PCB Stencil Laser Cutting Machine, PCB Cutting, PCB Component Lead Cutting Machine, PCB Stencil Cutting, PCB V Cutting Machine, PCB Board Cutting Machine, PCB Laser Cutting Machine

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com